Increase Coolant Life, Reduce Coolant Purchases.

The PRAB Drum-Type Scraper Separator provides high-quality separation that is applicable to aluminum, non-ferrous, and composite materials. The unit does not consume any filtration materials, savings that go directly to your bottom line.

PRAB’s Drum-Type Scraper Separator is designed for industrial use in the following applications:

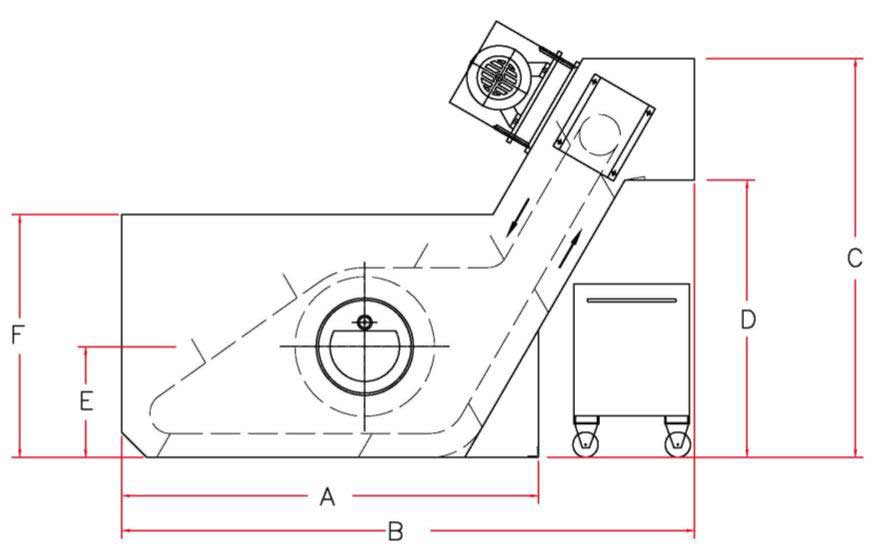

Dirty coolant enters the system through the back of the Drum-Type Scrap Separator. The coolant passes through the filter sleeve inwardly into the clean tank. The chips and solids retained by the sleeve will be flushed off the filter by an internal back flushing spray bar. The solids will drop to the bottom of the separator and will be removed on a continuous basis by the drag conveyor system. As the chips slowly move up the incline, the coolant will drain from the chips back into the filter, minimizing moisture on the chips.

Product Brochures

Product Brochure: Drum-Type Scraper Separator

White Paper

White Paper: Green Engineering

Other Downloadable Content

PRAB Fluid Filtration Solutions Product Selection Chart Brochure

PRAB Fluid Filtration Systems and Wastewater Treatment Brochure

PRAB Filtration Spectrum Brochure

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

PRAB completes comprehensive sample testing to establish an accurate understanding of the unique characteristics of your mixed solution and its industrial applications. This test determines the correct centrifuge system design and capacity to optimizes the filtration process within your facility.

To receive a free test contact us today at (800) 968-7722.

Automated fluid recycling systems maximize the service life of tools while lowering operating costs.By Mike Hook, Sales & Marketing Director, PRAB Introduction The metalworking industry, like all manufacturing operations, must contest with several market factors that are difficult if not impossible to control: Escalating materials costs spurred by policy decisions, transportation costs, raw materials […]

Proven Reduction of New Fluid Purchases Up to 75%Lower Your Maintenance Costs & Boost Your Bottom Line PRAB Drum-Type Scrap Separators provide high-quality separation that is applicable to aluminum, non-ferrous, and composite materials. The unit does not consume any filtration materials, savings that go directly to your bottom line. Top Features & Benefits: Increases coolant […]

Proven to Reduce Haul-Away Costs Up to 90% Separation Spectrum Whether you need to simply separate swarf from coolant, clean wash water for reuse, or achieve clarity acceptable to your local municipality, all PRAB equipment and systems are designed for your specific application. Find your application or separation process on the chart below. Contact us […]